What is thermal grease?

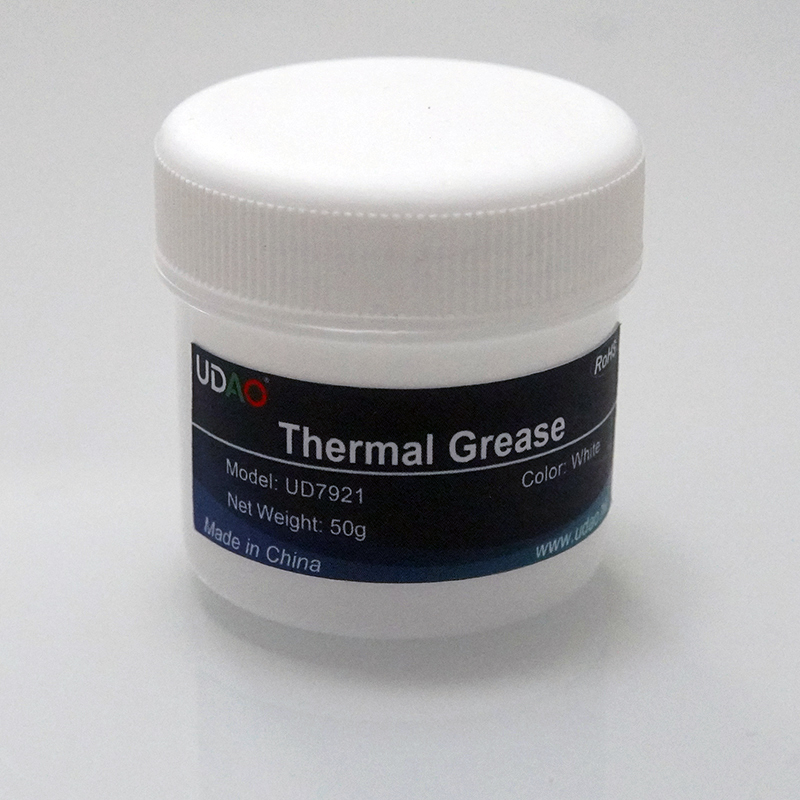

Thermal grease, also known as thermal paste, thermal compound and heatsink paste, is a highly thermally conductive insulating material. It can maintain its paste state for a long time at a temperature of -50℃-+200℃. It has good insulation and excellent thermal conductivity.

It is specially developed for the heating of various electrical equipment and the heat dissipation and insulation requirements of electronic components.

It is non-toxic, odorless, non-corrosive, and complies with environmental protection requirements such as RoHS,Reach , HF, MSDS, etc., and has stable chemical and physical properties.

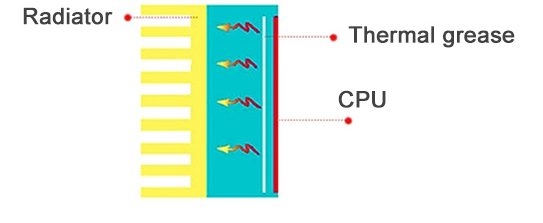

Thermal conduction principle:

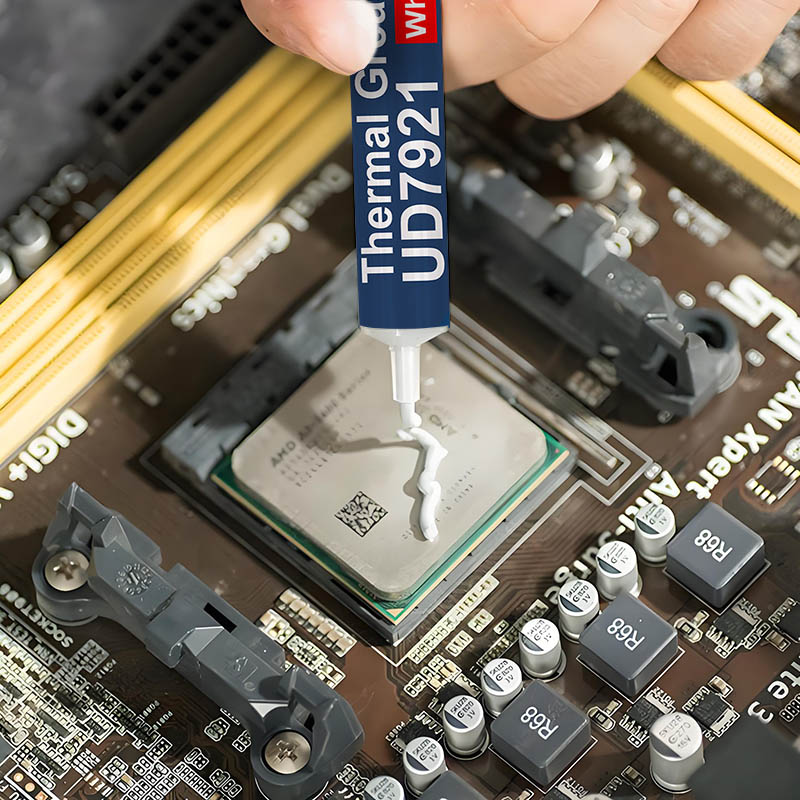

Thermal grease is used to fill the gap between the heating element and the heat sink, increasing their contact area, thereby achieving a good thermal conductivity effect. Its excellent thermal conductivity can effectively transfer the heat emitted by electronic components when they are working.

How to choose thermal paste?

w is the unit of thermal conductivity:watt.

Thermal conductivity can also be understood as the thermal conductivity level. The higher the thermal conductivity, the better the thermal conductivity.

Product Features:

•High thermal conductivity.

• non-conductive.

• non-curing.

• high temperature resistance.

• low oil separation.

• non-corrosive.

Range of Applications:

Thermal grease is widely used in heat conduction and heat dissipation of electronic products such as computer CPU, LED, smart speakers, power modules, drones, learning machines, photovoltaics, new energy, semiconductor chips, etc.

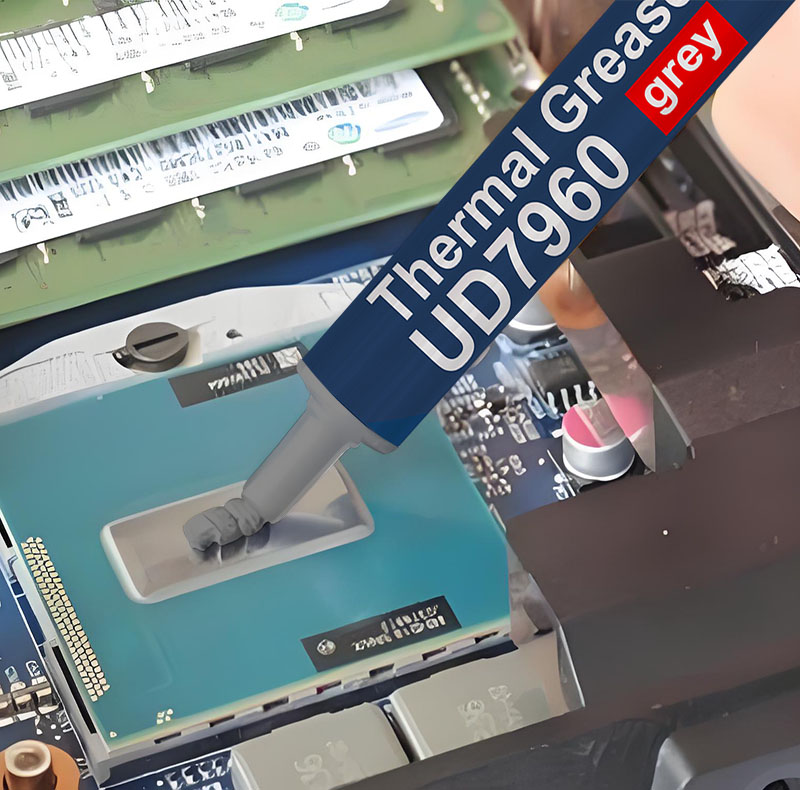

Thermal paste application tutorial

1.Clean the surface of the CPU

3.Spread the thermal grease

with a spatula or brush

2.Apply thermal paste in the

of CPU

4.Spread the hea conductive

silic grease evenly t thickness

of the sheet

Specification:

| Testing Item | Unit | Testing Method | Testing Value |

| Thermal Conductivity | W/M.K | ASTM D5470 | 6.0(±0.2) |

| Colour | – | Visual | grey |

| Thermal Resistance | ℃-in2/W | ASTMD1475 | ≤0.051 |

| Specific Gravity | (25℃)g/cm³ | ASTMD1475 | >2.4 |

| Evaporation | % | Fed.Std.791 | <0.1 |

| Oil Precipitation | % | Fed.Std.791 | <0.6 |

| Dielectric Constant | – | ASTM D150 | >5 |

| Cone Penetration | 1/10 MM | GB/T-269 | 280±10 |

| Weight loss | % | @200°200H | <1 |

| Working Temperature | ℃ | IEC 60068-2-14 | -50~200℃ |

Reviews

There are no reviews yet.