Thermal paste is a high-performance thermal conductive material (TIM) used to fill the tiny gap between the chip (CPU, GPU, IGBT, etc.) and the heat sink, reducing thermal resistance and improving heat dissipation efficiency. Proper application of thermal paste is critical in consumer electronics, servers, automotive electronics, 5G base stations, and power modules. In mass production, efficient and precise coating methods can improve product consistency and optimize heat dissipation performance.

Thermal grease application method:

1. Manual application method (suitable for small-scale or DIY applications)

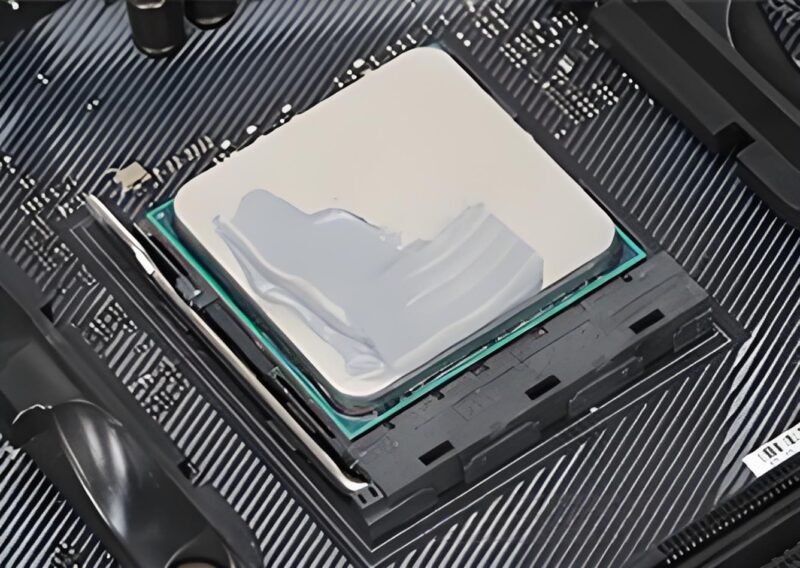

Dot method (suitable for small and medium-sized chips)

1.1: Method: Apply a small drop (rice-sized) of thermal paste to the center of the chip and let it spread naturally when installing the heat sink.

Advantages: Simple, no additional tools required, minimal waste.

Disadvantages: May not evenly cover large debris.

Spreading method (for larger chips)

Method: Use a plastic spatula or scraper to spread the grease into a thin, even layer.

Pros: Ensures full coverage, suitable for manual application.

Cons: May introduce air bubbles, reducing thermal conductivity.

Cross and Grid Patterns (for rectangular or large chips)

Method: Apply thermal grease in a cross or grid pattern using a dispensing gun or spatula.

Advantages: Ensures even distribution, ideal for server CPUs and IGBT modules.

Disadvantages: Requires high-flow grease for smooth application.

Mass Application Methods (for high-volume production)

In order to improve the efficiency and consistency of industrial production, large-scale thermal grease application uses specialized equipment, including stencil printing, automatic dispensing, spraying, and rolling.

Stencil Printing – For Standardized Mass Production

Principle: Similar to SMT solder paste printing, thermal grease is applied through a stencil.

Applications: Server CPUs, power modules, large heat sinks.

Advantages:Precisely control grease thickness (e.g. 0.1 mm, 0.15 mm) for even application.

Ideal for mass production, improving efficiency.

Disadvantages:Requires customized stencils and equipment.

The stencil holes must match the grease viscosity to prevent clogging or overflow.

Automatic dispensing – for high-precision applications

Principle: Use an automatic dispenser to apply a controlled amount of thermal paste.

Applications: BGA chips, IGBT modules, power management ICs.

Advantages:Programmable control ensures accurate dispensing of different chip sizes.

Compatible with high-viscosity and low-viscosity thermal greases.

Disadvantages:High equipment cost, suitable for industrial production.

Bubbles may form and dispensing parameters need to be optimized.

Spraying – for ultra-thin coatings

Principle: Use a spraying system to atomize and evenly apply the grease.

Applications: Thin film cooling solutions, 5G base stations, ultra-thin chip cooling.

Advantages:Forms a uniform, ultra-thin coating to minimize thermal resistance.Suitable for large area coverage and improved production efficiency.

Disadvantages:Requires complex equipment calibration to control thickness and uniformity.If the parameters are not optimized, material waste may occur.

Roller coating – suitable for large-area heat sink applications

Principle: Use a coating roller to evenly apply thermal grease to large heat sinks or substrates.

Applications: Large heat sink bases, IGBT module substrates.

Advantages:Can be evenly applied on large surfaces, suitable for industrial cooling solutions.

The equipment operates stably and is suitable for mass production.

Disadvantages:Limited to flat surfaces, not suitable for complex heat sink designs.Common mistakes and key considerations

For personal use, manual application is sufficient, while industrial production requires automated equipment to ensure consistency and efficiency. Choosing the right thermal paste application method can enhance heat dissipation, improve product stability, and extend the life of the device.